Company brochure

English

for heavy fuel oil fired boilers

PentoMuls | Water-in-Oil Technology for HFO Boilers

For complete carbon burnout and increased efficiency

PentoMag® | Additive for HFO Boilers

For protection and heat transfer optimization

English

Spanish

Russian

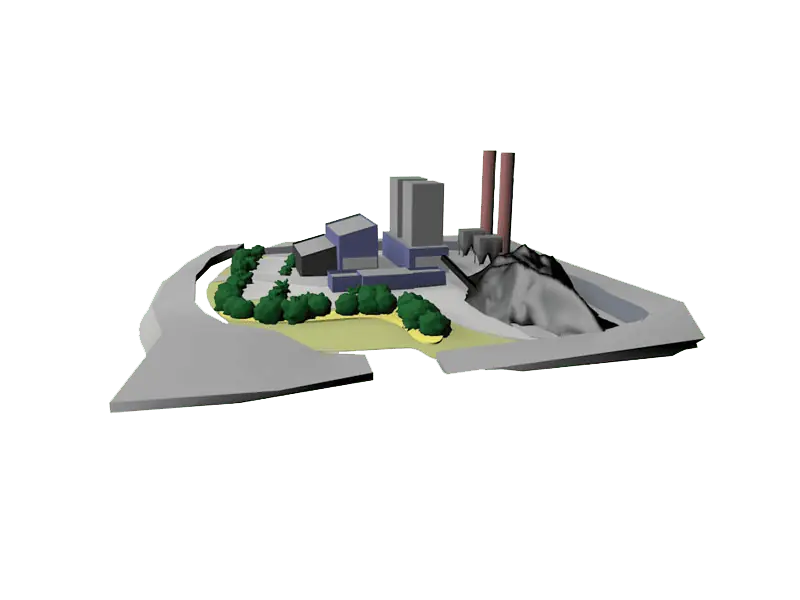

for coal fired boilers

PentoMag® | Additive for Coal Boilers

#Fight Coal Slagging and #Deposits in the Boiler

Flue Gas Conditioning for Coal Boilers (FGC)

For #Dust Emission Reduction and #Gypsum Quality Improvement

for stationary diesel engines

PentoMag® | Additive for Stationary Diesel Engine

#Increase Efficiency and #Avoid Corrosion and Deposits

for marine diesel engines

PentoMag® | Additive for Marine Diesel Engine

#IMO 2020 and #VLSFO additive

for Cement Plants

PentoMag® | Additive for Gas Turbines

#Avoid Corrosion and #Increase Efficiency

for Gas turbines

PentoMag® | Additive for Gas Turbines

#Avoid Corrosion and #Increase Efficiency

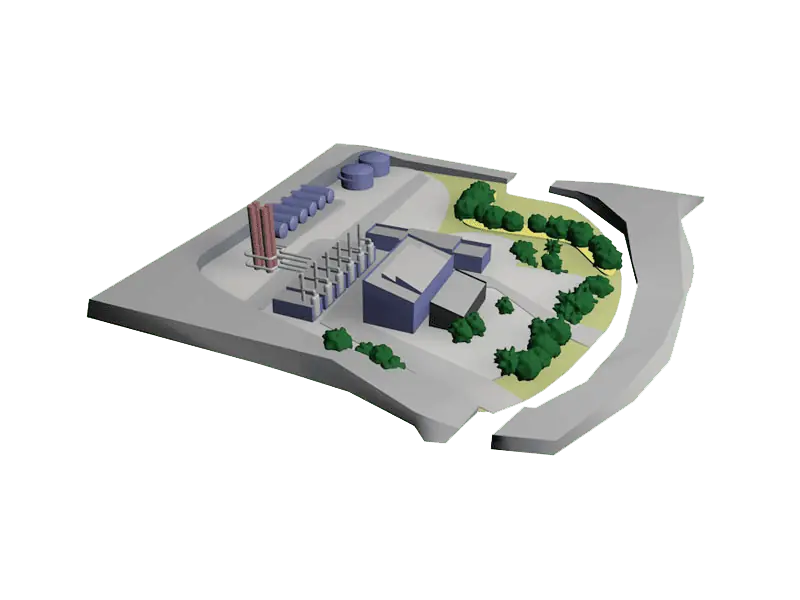

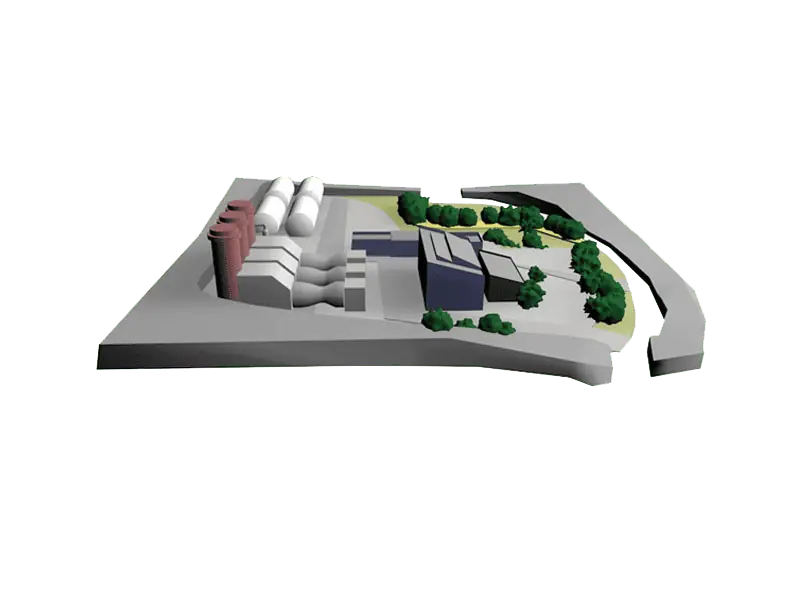

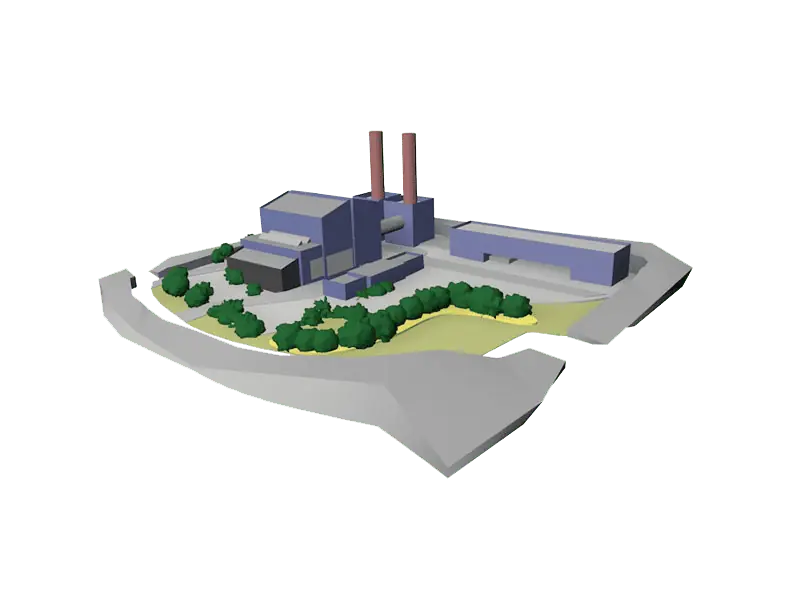

for Incinerators

PentoMag® | Additive for Incinerators

#Reduce Slagging and Corrosion in Biomass Plants and Waste Incinerators

Chlorine Conditioning for Incinerators

#Reduce Corrosion on Super Heaters

for all plant types

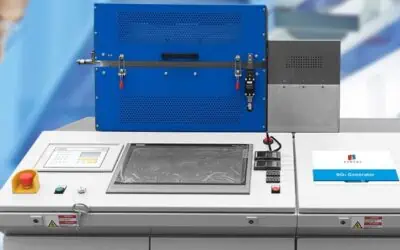

SO3 Monitor

#Measuring and #Analyzing

SO3 Generator

For Industrial Applications and Laboratory Use

English

PentoSolv3 | Cleaning Agent for all Power Plant Types

Cleaning of #Heating Surfaces and #Intercoolers

English