PentoMag® | Additive for Incinerators

#Reduce Slagging and Corrosion in Biomass Plants and Waste Incinerators

Summary

PentoMag® is designed to avoid corrosions and deposits

![corrosion-incinerator[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/corrosion-incinerator1.png)

The waste incineration furnace is one of the most widespread and technically most interesting systems for disposing of the waste of industrial or private origin.

These products still contain a certain latent energy. Through combustion part of their energy potential is released and can be used to create electrical power or heat. The other aspect, perhaps as important, is that through the incineration furnace, a reduction in the volume of waste products of around 90% and around 70% in weight is obtained.

These major reductions, associated with the fact that the residue slag from the combustion process is sterile and completely mineralized, are another point in favor of incineration furnace technology.

Whether you optimize combustion of a waste incinerator, a fuel or coal-fired boiler, a gas turbine or diesel engine, you are always required to see the combustion process as a whole and not just look at the combustion chamber for improvement possibilities.

At Pentol, we have been optimizing such processes since 1969 and since then, these processes have been developed further in many ways. The fuel composition and its storage are as important as the firing technology, the selection of the proper steel for tubing and the gas cleaning.

Before offering a treatment solution, Pentol is analyzing the situation in your plant and will check which technology could be most promising to achieve the goals set.

Being a magnesium-based product, PentoMag® offers a very general approach to neutralize acidic deposits. For this reason, the source of corrosion should be identified before treatment.

Wirkungsprinzip

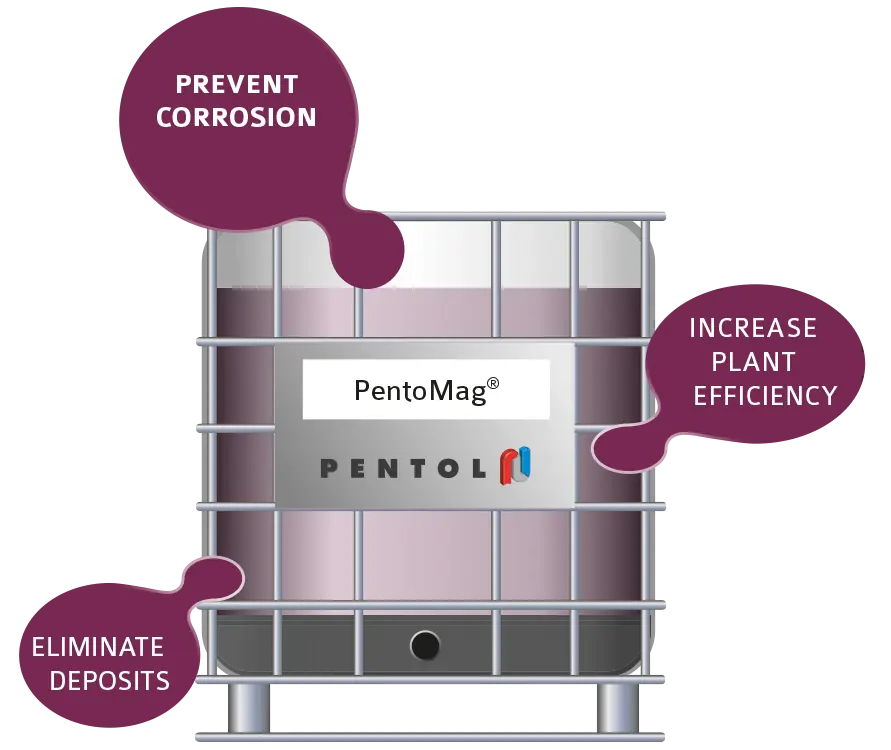

Increase pH and melting points

![wasteincinerator-corrosion[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/wasteincinerator-corrosion1.png)

The main source of corrosion are acid gases contained in flue gas

During the combustion stage, fly ash is generated which, dragged by the warm gas current and given its rather plastic and semi-molten state, clings to the walls of the furnace covering the top of the post-combustion chamber and the steam generator pipes.

The deposits grow in the most critical areas (the side walls, the top of the furnace towards the post-combustion chamber) and reduce heat exchange capacity, exerting an abrasive action on the boiler pipe bundle.

Along with the growing deposits on the pipes and walls inside the furnace, a higher temperature is required to obtain the proper steam temperatures leading to higher NOx emission values.

Contributing to these effects are

• SO2 and SO3

• Halogenated acids (HCl, HF)

• Sodium based compounds.

Typically, the fouling inside the furnace reduces the load of the plant and will dictate, when the plant needs to shut down for cleaning.

Pentol brings nearly 50 years of experience in the treatment of deposits inside boilers using various fuels. Our intention with PentoMag® for waste incinerator plants is

• to extend the time of maximum load of the plant

• increase the efficiency of the plant

![waste-incinerator-corrosion[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/waste-incinerator-corrosion1.png)

Benefits

Increase the availability of the plant

![incinerator-shutown[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/incinerator-shutown1.png)

The most significant indication is the change brought by magnesium oxide on the morphology of the deposits, the increase of the pH of the ash collected on the superheater pipes, along with the discharge hoppers and their aspect.

The ash of the line not treated with PentoMag® has a very dark colour, is moist, with a high degree of cohesion, and is heavy, with a pH in a clearly acid field (pH varying between 4 and 5).

With PentoMag® conditioning, however, the remaining deposits are much smaller in size, more porous, have a lower density and are less humid in nature. Therefore they are easy to be removed by soot blowing. pH of remaining deposits can be measured to be 6-7 in the colder areas upstream of the electro filter to a maximum of 10 to 10.5 in the area of the superheater.

Another important aspect found after some months conditioning concerns the temperature of the superheated steam. The treated line maintains values close to the theoretical value while the other one shows a significant reduction, which even reaches 20°C. This temperature drop is the result of the insulating effect of the deposits resulting from the reduction in the heat exchange of the superheater pipes of the recovery boiler.

Dosing skid

High reactivity micronised magnesium oxide in diesel oil suspension

![micronized-magnesium[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/micronized-magnesium1.png)

![magnesium-incinerator[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/magnesium-incinerator1.png)

The continuous use of PentoMag® increases the pH of the dust effectively countering the acid compounds present in the combustion gas and helps the formation of particular eutectics at higher melting points thanks to the reactivity between Mg oxide in relation to the low-melting sodium compound present in the fly ash produced in waste combustion.

These new formations appear no longer very hard and tenacious, but more friable and with a clearly higher melting point, and therefore easier to remove.

Given the micronized state of the Mg oxide and the high turbulence of the area of its input, the acidity of the flue gas is reduced, due to the chemical reactions which occur between the acid gas and PentoMag® that is introduced.

By being distributed uniformly on the pipes, the Mg oxide provides a protective layer which prevents the onset of corrosion phenomena due to the condensation of the acid-reaction compounds, at the same time reducing erosion by the particles suspended and dragged by the gas current.

Maintenance

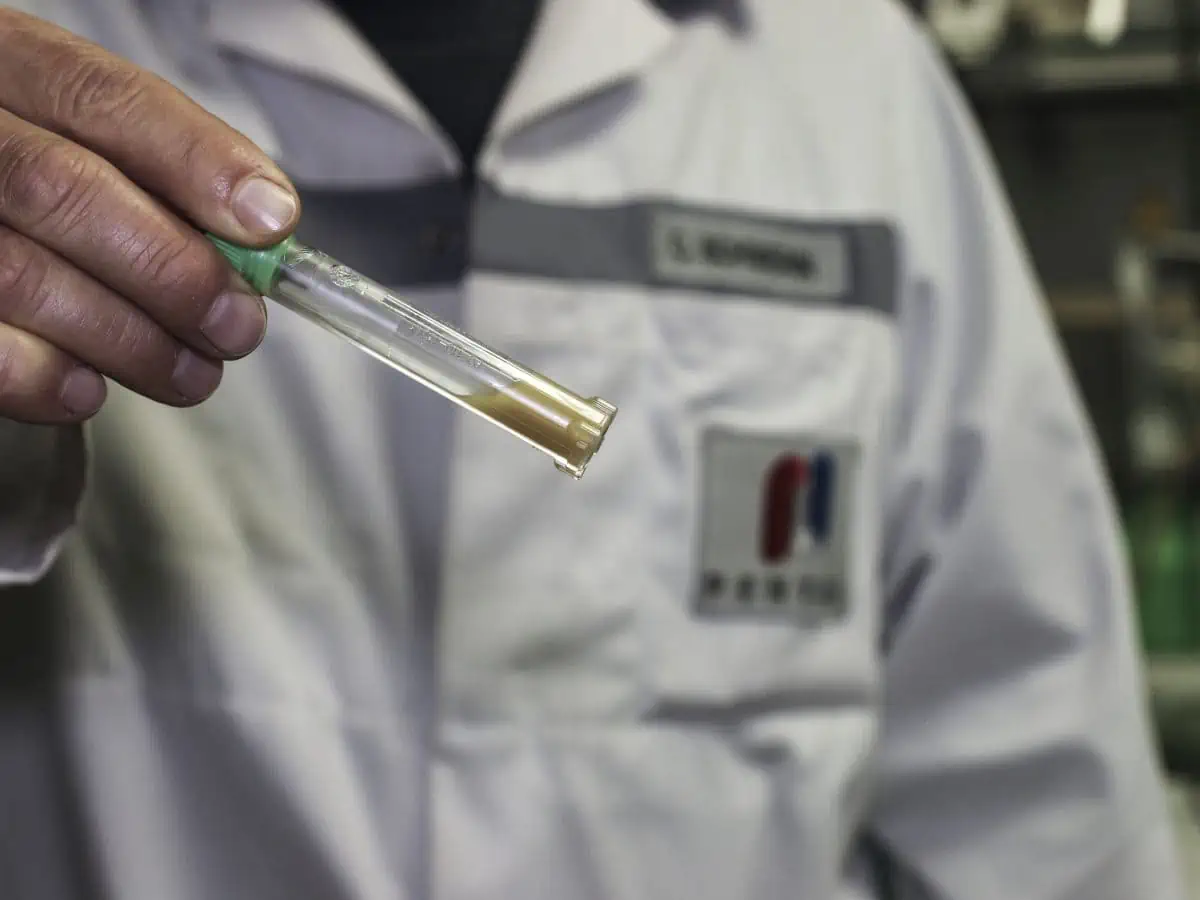

PentoMag® is added by means of dosage pumps connected to a storage tank

![waste-chlor-corrosion-11[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/waste-chlor-corrosion-111.jpg)

PentoMag® is added by means of dosing pumps connected to one or more injectors that are installed at crucial points in the furnace, identified by internal inspections.

PentoMag® is dispersed directly into the furnace through a water-cooled nozzle, that guarantees correct distribution of the product in the upward current of combustion gases.

The injector is connected to the compressed air circuit of the plant, with a minimum pressure of 4 bar.

The effectiveness of the treatment is controlled by measuring the pH of the fly ash, the situation of the operating parameters, such as temperature of the superheated steam, steam generator capacity and operating hours.

For every project, Pentol supplies a custom designed dosing skid and injector probes that fit the diameter of the flue gas duct.

Based on our experience we know about the importance of a continuous and reliable injection of our products to reach the best possible results.

The injector probes are water or air cooled depending on the temperature of the injection place. PentoMag® is atomized with compressed air and distributed across the cross-section of the flue gas duct. The length of the injector is adjusted to the local situation.

The dosing skid includes rugged metering pumps requiring a minimum of service. An active spare pump offers a very high availability of the dosing system.

Efficiency

Increase the availability of the plant

![incinerator-additives-1[1]](https://www.pentol.net/de/wp-content/uploads/2020/11/incinerator-additives-11.png)

The most significant indication is the change brought by magnesium oxide on the morphology of the deposits, the increase of the pH of the ash collected on the superheater pipes, along with the discharge hoppers and their aspect.

The ash of the line not treated with PentoMag® has a very dark colour, is moist, with a high degree of cohesion, and is heavy, with a pH in a clearly acid field (pH varying between 4 and 5 ).

With PentoMag® conditioning, however, the remaining deposits are much smaller in size, more porous, have a lower density and are less humid in nature. Therefore they are easy to be removed by soot blowing. pH of remaining deposits can be measured to be 6-7 in the colder areas upstream of the electro filter to a maximum of 10 to 10.5 in the area of the superheater.

Another important aspect found after some months conditioning concerns the temperature of the superheated steam. The treated line maintains values close to the theoretical value while the other one shows a significant reduction, which even reaches 20°C. This temperature drop is the result of the insulating effect of the deposits resulting from the reduction in the heat exchange of the superheater pipes of the recovery boiler.

Corrosion and perforation of the recovery boiler pipes

Drastic reduction in the areas most subject to stress, such as superheater pipes, and complete protection of the whole metal frame in the cold part of ash collection from the electro filters

Improved heat exchange rates

More efficient recovery boiler and therefore to greater use of the steam produced with a higher enthalpy value

Formation of friable deposits

light and easy to remove with soot blowers

Reduction in the scrubbing times

of the flue gas thanks to the high friability of the deposits present.

Cleaning of the electrodes

Greater efficiency of the electro filters and the sleeve filters

Tell us your opinion

Leave us a short feedback

Download PDF

ADDITIVE – PentoMag for Incinerators