Navigation | Keynote | Summary |Action principle | Benefits | Dosing skid | Maintenance | Efficiency | Next steps | Tell us your opinion | Downloads | Cases

PentoMag® for Diesel has been developed with three goals in mind:

- Protect the diesel engine and turbo loader from corrosion and deposits

- Reduce emission

- Reduce fuel consumption

PentoMag® for Diesel is the result of a deep cooperation with one of our clients, where this additive has been developed custom designed for the clients need.

PentoMag® for Diesel is more than a corrosion inhibitor.

It´s a balanced blend of

- cracking-catalysts

- fuel-homogenizers

- combustion-catalysts

- corrosion-inhibitors

PentoMag® for Diesel increases the overall efficiency of diesel engines by around 5%.

This may sound unbelievable, but we can achieve this goal by optimizing not only the engine itself, but most of all the fuel oil treatment station.

![diesel-so3-additive1[1]](https://www.pentol.net/wp-content/uploads/2020/11/diesel-so3-additive11.webp)

Reduce sludge from storage tanks and burn it with the help of the combustion improver

![diesel-so3-additive2[1]](https://www.pentol.net/wp-content/uploads/2020/11/diesel-so3-additive21.webp)

Neutralize corrosion in turbo and recovery boiler

![diesel-so3-additive3[1]](https://www.pentol.net/wp-content/uploads/2020/11/diesel-so3-additive31.webp)

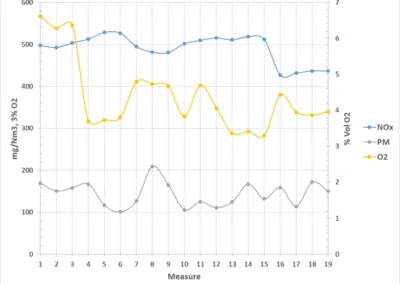

Reduce emission

Dispersing of asphaltenes

![01-1024x732[1]](https://www.pentol.net/wp-content/uploads/2020/11/01-1024x7321-1.webp)

Reducing the amount of sludge disposed

![02-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/02-11.webp)

The additive includes sludge dispersing solvents and water emulsifiers

![03-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/03-11.webp)

Increasing the net calorific value

![gas-turbine-maintanence[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-maintanence1.webp)

![Bild2[1]](https://www.pentol.net/wp-content/uploads/2020/11/Bild21.png)

![sludge-diesel[1]](https://www.pentol.net/wp-content/uploads/2020/11/sludge-diesel1.webp)

Combustion catalyst

Increase combustion surface and speed

The catalyst in PentoMag® 4400 evokes a reduction of the activation energy of the fuel.

- carbon burn out is more complete

- less oxygen needed

- producing less smoke and ash

- more efficiency reduces fuel consumption

![Bild1[1]](https://www.pentol.net/wp-content/uploads/2020/11/Bild11.webp)

![diesel-engine-sludge2[1]](https://www.pentol.net/wp-content/uploads/2020/11/diesel-engine-sludge21.webp)

Vanadium inhibitor

![Bild3-554x554[1]](https://www.pentol.net/wp-content/uploads/2020/11/Bild3-554x5541-1.webp)

![deposit-turbo-corrosion1[1]](https://www.pentol.net/wp-content/uploads/2020/11/deposit-turbo-corrosion11.webp)

![deposit-turbo1[1]](https://www.pentol.net/wp-content/uploads/2020/11/deposit-turbo11.webp)

Availability

Reducing fouling leads to

- reduced maintenance work

- extended lifetime

Pentol expects a fuel oil saving in the order of 2-5 %, depending on the fuel characteristics, combustion parameters and the general condition of the diesel engine.

![combustion-additive[1]](https://www.pentol.net/wp-content/uploads/2020/11/combustion-additive1.webp)

Dosing Equipment

![diesel-generator-sludge-11[1]](https://www.pentol.net/wp-content/uploads/2020/11/diesel-generator-sludge-111.webp)

We offer a range of individual dosing equipment with minimal maintenance and maximal precision.

Get support from Pentol at

- Storage of chemicals

- Commissioning of dosing unit

- Setting up individual parameters

- Emission measurement and monitoring