PentoMag® | Additive for Furnace and FCC units

For protection and heat transfer optimization

Summary

High-temperature corrosion on heat transfer surfaces

![power-plant-emission-controll1[1]](https://www.pentol.net/wp-content/uploads/2020/10/power-plant-emission-controll11.jpg)

PentoMag® is our brand name for a group of magnesium-based products. Using magnesia of different origin and form, we prevent the formation of vanadium deposits and neutralize sulfuric acid.

Pentol produces both additives as well as automatic dosing equipment for the protection and efficiency increase of your furnace.

Action principle

High-temperature corrodes on heat transfer surfaces

Fuel oil components with low melting point form molten ash components and stick to the surface of furnace walls, superheaters, reheaters, and economizers.

Growing deposits set a long sequence of compensation actions into gear.

Heat transfer is reduced. The gas temperature needs to be raised to keep the steam quality constant.

With rising gas temperature, more ash is collected on the pipes, increasing the deposit problem.

The deposits formed contain different forms of Vanadium oxides. These are corrosive by themselves and act as catalyst to oxidize SO2 to SO3.

![heat-pipe-corrosion_011[1]](https://www.pentol.net/wp-content/uploads/2020/10/heat-pipe-corrosion_0111.gif)

![corrosion-power-station_01-1024x4711[1]](https://www.pentol.net/wp-content/uploads/2020/10/corrosion-power-station_01-1024x47111-1.png)

The SO3 moves to the cold end of the furnace and condenses on surfaces with temperatures below acid dew point (ADP). This is especially the case in the rotary air heater, where SO3 condenses and forms sulfuric acid deposits.

Sulfuric acid is very corrosive and forms deposits in the same time, blocking the gas passage.

After a few month, a service shutdown is necessary to repair puncture holes or clean the gas passage.

Benefits

Minimize maintenance and furnace temperature

PentoMag has a great influence on fusion temperature of ash independent of the fuel components.

With PentoMag® vanadium loses its catalytic power, becoming inert and breaks the chain of corrosion damages and heat transfer losses. Vanadium is removed from the furnace tubes and cannot catalyst SO2 anymore.

In the cold-end, this allows to create a corrosion-free environment, neutralizing all condensing SO3 and increasing the time between shutdowns.

Reduce corrosive deposits on furnace walls, superheaters, reheaters, and economizers.

Reduce fouling of air preheater from acidic corrosion.

Reduce costs through the decrease of exit gas temperature.

Reduce fouling of air preheater from acidic corrosion.

Reduce costs through the decrease of exit gas temperature.

Reduce corrosive deposits on furnace walls, superheaters, reheaters, and economizers.

Reduce fouling of air preheater from acidic corrosion.

Reduce costs through the decrease of exit gas temperature.

Reduce fouling of air preheater from acidic corrosion.

Reduce costs through the decrease of exit gas temperature.

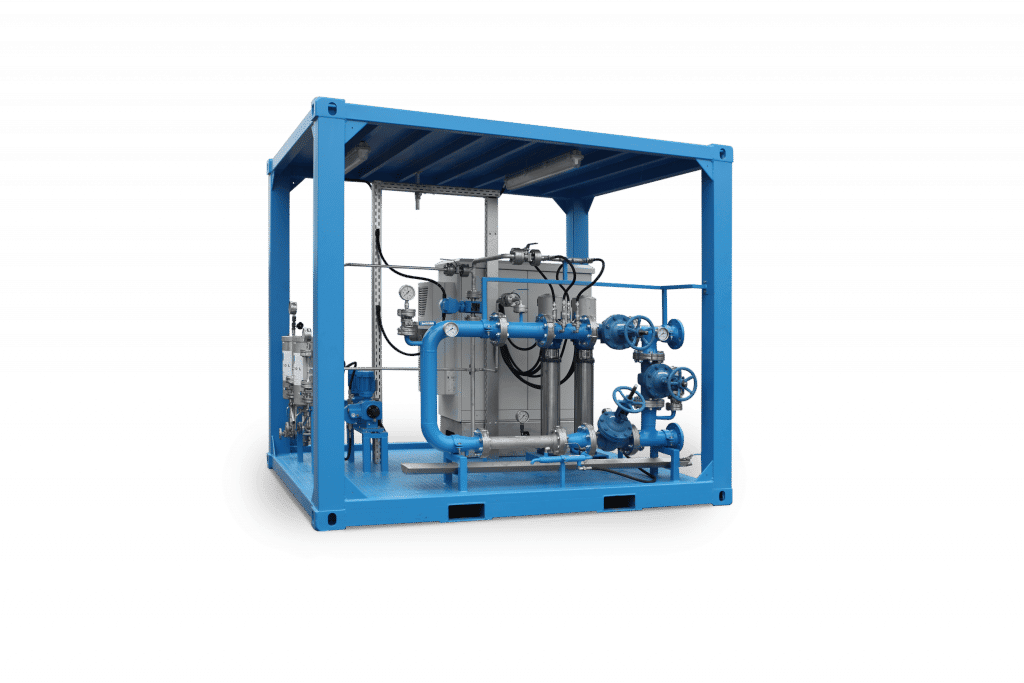

Dosing skid

Tailored blends from the range of specialty chemicals

![magnesium-oxide-combustion1[1]](https://www.pentol.net/wp-content/uploads/2020/10/magnesium-oxide-combustion11.png)

As each furnace is different, it requires specific treatment to gain optimum results and to maximize savings.

With 50 years of experience protecting furnaces from corrosion, Pentol has learned to chose the right chemistry to provide the best price-performance ratio.

Our most advanced solutions are based on a mixture of organic and inorganic magnesium oxide, making use of the best of two chemical worlds

We offer a full scope of products perfectly balanced from magnesium based on magnesium oxide (MgO), magnesium carboxylate and magnesium sulfonate.

Pentol manufactures a multipurpose, wide range of specialty chemicals for fuel oil treatment to gain optimum results and maximize savings for each furnace.

To receive a quote, please talk to a sales engineer in order to find the best possible product for your application.

Maintenance

The combustion additive will be dosed in fuel line directly

![IMG_1110-600x4001[1]](https://www.pentol.net/wp-content/uploads/2020/10/IMG_1110-600x40011-1.jpg)

![IMG_5623-pmuls-600x4001[1]](https://www.pentol.net/wp-content/uploads/2020/10/IMG_5623-pmuls-600x40011-1.jpg)

Pentol manufactures pumps and systems for a precise and reliable fully automatic dosing.

Our scope of supply includes simple dosing systems for retrofits of power stations up to complex dosing systems that are integrated in the DCS.

Pentol worldwide stores spare parts in all countries where we have active clients and provides full service to our dosing equipment to ensure a constant and reliable injection of our additives.

We strongly believe that the service related to our products is key for a successful furnace treatment.

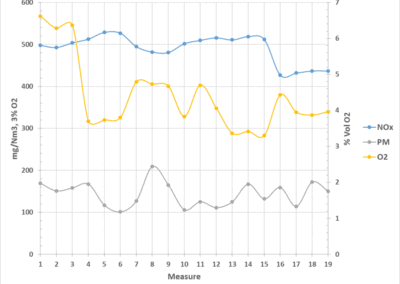

Efficiency

The application of a PentoMag® results in a list of improvements

![PentoMuls_Report_Ulsan-2-1024x7631[1]](https://www.pentol.net/wp-content/uploads/2020/10/PentoMuls_Report_Ulsan-2-1024x76311-1.jpg)

REDUCE MAINTENANCE WORK

Cleaning intervals for furnace, superheater, reheaters, economizers and air heaters are reduced. Dosing equipment designed by Pentol is of rugged design and requires minimum maintenance.

INCREASE PLANT AVAILABILITY

Reduced corrosion and deposits mean extended lifetime of high and low-temperature sections, allows longer cleaning intervals and less unexpected downtime.

INCREASE FURNACE EFFICIENCY

Improved heat transfer, lower O2 and atomising steam consumption, less soot blowing and particularly the possibility to reduce final gas temperature to a minimum, resulting in a substantial increase in furnace efficiency.

REDUCE CORROSION

PentoMag’s main property is to reduce high and low-temperature corrosion. Reduced corrosion means an extended lifetime of high and low-temperature sections in the flue gas duct.

REDUCE FOULING

Reduced fouling increases heat transfer in superheater and air heater sections and reduces downtime for cleaning.

REDUCE EMISSIONS

SO3 emission and the visible white chimney plume are reduced. With a reduction of exit gas temperature, the total efficiency of the plant can be increased, resulting in a reduced CO2 emission of the plant.

Pentol offers a unique way to improve the eco-efficiency of power plants.

PentoMag reduces acid smut emission and SO3 emission. Pentol is able to give you guarantees on maximum SO3 emission .

In combination with PentoMuls, we can

REDUCE SOLID EMISSION

REDUCE NOx EMISSION

REDUCE CO EMISSION

+

PREVENT CORROSION IN THE BACK END

PREVENT PLUGGING IN THE BACK END

=

INCREASE EFFICIENCY OF THE PLANT

PentoMag® eliminates SO3 and removes the plume of your chimney.

Reducing emission normally comes at a cost. Pentol’s main focus on developing environmental technology however is to reduce emissions by optimize the combustion. This approach is extremely interesting as the cost of Pentol’s fuel oil treatment is always covered by the economical benefits achieved.

Tell us your opinion

Leave us a short feedback

Download PDF

ADDITIVE – PentoMag® for HFO » EN

ADDITIVE – PentoMag® for HFO » ES

ADDITIVE – PentoMag® for HFO » RU

TREATMENT – Heavy Fuel Oil Boilers » EN