Navigation | Keynote | Summary |Action principle | Benefits | Dosing skid | Maintenance | Efficiency | Next steps | Tell us your opinion | Downloads | Cases

Reduce corrosion, fouling and steam leaks in boilers

![power-plant-emission-controll1[1]](https://www.pentol.net/wp-content/uploads/2020/10/power-plant-emission-controll11.webp)

High-temperature corrodes on heat transfer surfaces

![heat-pipe-corrosion_011[1]](https://www.pentol.net/wp-content/uploads/2020/10/heat-pipe-corrosion_0111.webp)

![corrosion-power-station_01-1024x4711[1]](https://www.pentol.net/wp-content/uploads/2020/10/corrosion-power-station_01-1024x47111-1.webp)

Minimize maintenance and boiler temperature

PentoMag has a great influence on fusion temperature of ash independent of the fuel components.

With PentoMag® vanadium loses its catalytic power, becoming inert and breaks the chain of corrosion damages and heat transfer losses. Vanadium is removed from the boiler tubes and cannot catalyst SO2 anymore.

In the cold-end, this allows to create a corrosion-free environment, neutralizing all condensing SO3 and increasing the time between shutdowns.

Reduce fouling of air preheater from acidic corrosion.

Reduce costs through the decrease of exit gas temperature.

Tailored blends from the range of specialty chemicals

![magnesium-oxide-combustion1[1]](https://www.pentol.net/wp-content/uploads/2020/10/magnesium-oxide-combustion11.webp)

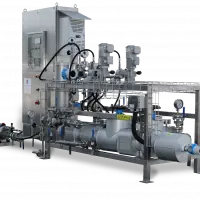

The combustion additive will be dosed in fuel line directly

![IMG_1110-600x4001[1]](https://www.pentol.net/wp-content/uploads/2020/10/IMG_1110-600x40011-1.webp)

![IMG_5623-pmuls-600x4001[1]](https://www.pentol.net/wp-content/uploads/2020/10/IMG_5623-pmuls-600x40011-1.webp)

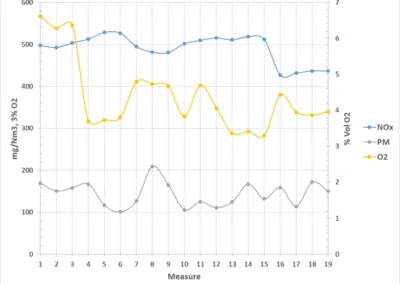

The application of a PentoMag® results in a list of improvements

![PentoMuls_Report_Ulsan-2-1024x7631[1]](https://www.pentol.net/wp-content/uploads/2020/10/PentoMuls_Report_Ulsan-2-1024x76311-1.webp)

Leave us a short feedback

Download PDF

English

Spanish

Russia

English