Navigation | Keynote | Summary |Action principle | Benefits | Dosing skid | Maintenance | Efficiency | Next steps | Tell us your opinion | Downloads | Cases

PentoMag® 4450 has been developed with three goals in mind:

1. Protect the diesel engine and turbo loader from corrosion and deposits

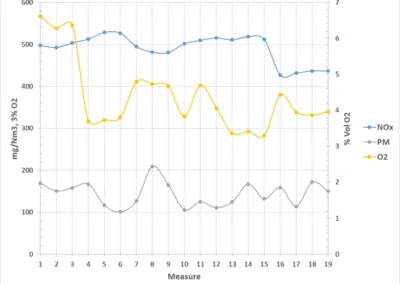

2. Reduce emission

3. Reduce fuel consumption

PentoMag® 4450 is the result of a deep cooperation with one of our clients, where this additive has been developed custom designed for the clients need.

PentoMag® 4450 is more than a corrosion inhibitor.

It´s a balanced blend of

- cracking-catalysts

- fuel-homogenizers

- combustion-catalysts

- corrosion-inhibitors

PentoMag® 4450 increases the overall efficiency of diesel engines by around 5%. This may sound unbelievable, but we can achieve this goal by optimizing not only the engine itself, but most of all the fuel oil treatment station. Read the following pages to get an impression on how we can achieve this goal and get in contact with one of our combustion engineers to discuss the possibility of testing PentoMag® 4450 on your gas turbine.

![gas-turbine-additive01-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-additive01-11.webp)

![gas-turbine-additive02-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-additive02-11.webp)

![gas-turbine-additive03-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-additive03-11.webp)

Dispersing of asphaltenes

![01-1024x732[1]](https://www.pentol.net/wp-content/uploads/2020/11/01-1024x7321-1.webp)

![02-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/02-11.webp)

![03-1[1]](https://www.pentol.net/wp-content/uploads/2020/11/03-11.webp)

![gas-turbine-maintanence[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-maintanence1.webp)

![Bild2[1]](https://www.pentol.net/wp-content/uploads/2020/11/Bild21.png)

![sludge-diesel[1]](https://www.pentol.net/wp-content/uploads/2020/11/sludge-diesel1.webp)

Combustion catalyst

![gas-turbine-pentomag4450-xxxman_flame-1200x9001[1]](https://www.pentol.net/wp-content/uploads/2020/11/gas-turbine-pentomag4450-xxxman_flame-1200x90011-1.webp)

![turbine-combustion-additive01[1]](https://www.pentol.net/wp-content/uploads/2020/11/turbine-combustion-additive011.webp)

![turbine-combustion-additive02[1]](https://www.pentol.net/wp-content/uploads/2020/11/turbine-combustion-additive021.webp)

![turbine-combustion-additive03[1]](https://www.pentol.net/wp-content/uploads/2020/11/turbine-combustion-additive031.webp)

Vanadium inhibitor

![gasturbine-corrosion[1]](https://www.pentol.net/wp-content/uploads/2020/11/gasturbine-corrosion1.webp)

![turbine-combustion-additive04[1]](https://www.pentol.net/wp-content/uploads/2020/11/turbine-combustion-additive041.webp)

Availability

![combustion-additive[1]](https://www.pentol.net/wp-content/uploads/2020/11/combustion-additive1.webp)

Dosing Equipment

![gasturbine-corrosion1[1]](https://www.pentol.net/wp-content/uploads/2020/11/gasturbine-corrosion11.webp)