Welcome to PENTOL!

We are the specialists for combustion optimization for boilers,

gas turbines and diesel engines.

PentoMag® | Additive for Furnace and FCC units

For protection and heat transfer optimization

PentoMag for Sour Gas

To treat sour gas and protect your recovery boiler.

PentoMag® | Additive for Marine Diesel Engine

#IMO 2020 and #VLSFO additive

PentoMuls | Water-in-Oil Technology for HFO Boilers

For complete carbon burnout and increased efficiency

PentoMag® | Additive for HFO Boilers

For protection and heat transfer optimization

PentoMag® | Additive for cement plants

For coating control and plant efficiency

Flue Gas Conditioning for Coal Boilers (FGC)

For #Dust Emission Reduction and #Gypsum Quality Improvement

PentoMag® | Additive for Coal Boilers

#Fight Coal Slagging and #Deposits in the Boiler

PentoMag® | Additive for Stationary Diesel Engine

#Increase Efficiency and #Avoid Corrosion and Deposits

PentoMag® | Additive for Gas Turbines

#Avoid Corrosion and #Increase Efficiency

PentoMag® | Additive for Incinerators

#Reduce Slagging and Corrosion in Biomass Plants and Waste Incinerators

Chlorine Conditioning for Incinerators

#Reduce Corrosion on Super Heaters

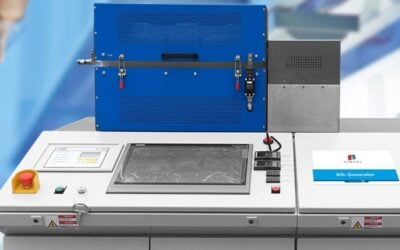

SO3 Generator

For Industrial Applications and Laboratory Use

SO3 Monitor

#Measuring and #Analyzing

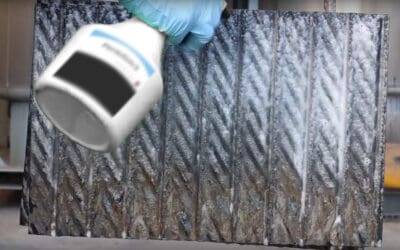

PentoSolv3 | Cleaning Agent for all Power Plant Types

Cleaning of #Heating Surfaces and #Intercoolers

AGAM System

ACOUSTIC GAS TEMPERATURE MEASUREMENT

CEMS

Continuous Emission Measurement System

Upcoming events

Meet us in 2023 on ICCI Istanbul and Enlit Europe Paris. More information about booth numbers coming soon.

Enlit Asia, Bangkok

Greetings from Bangkok. Great being in Thailand and seeing everyone on our booth 1517.We were there from September 20th to 23rd

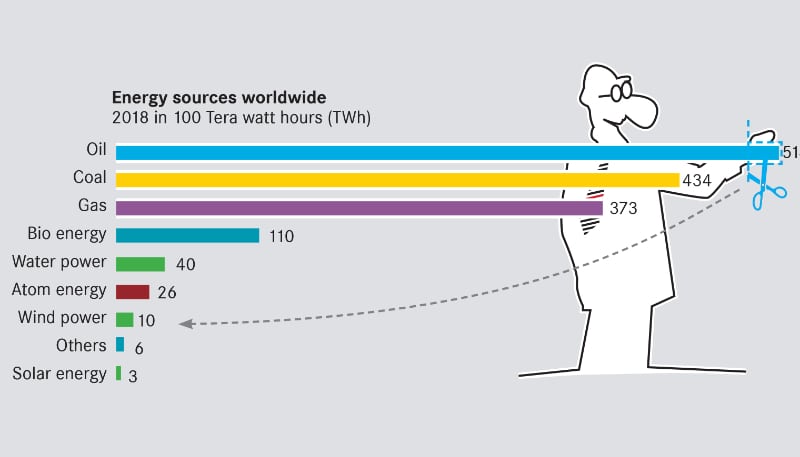

How we can help coal-fired power plants in the current geopolitical situation

Financial Times EU prepares to sell more carbon permits to pay for exit from Russian gas ...diplomats told the Financial Times. The permits allow their users to emit more carbon. The commission has a plan for Europe to invest around €200bn... MAY 17,...

Additives and technology for power plants

Click on play to see the big picture in combustion optimization

CASES – Cleaning airfilters with PentoSolv 3

Cleaning heat exchanger surfaces, boiler walls, fuel oil centrifuges, cylinder heads etc. with PentoSolv 3.

CASES – SO3 monitoring as part of the quality control

Management Summary – IBIDEN Porzellanfabrik

CASES – Burns heavy fuel oil with 16% asphaltenes and 7% sulphur

Client: Energoimport ► Task: Nuevitas Power Station – Burns heavy fuel oil with 16% asphaltenes...

The Power Plant Optimization Company

Since 1969 PENTOL is a well known name in the world of power plants. Our technical engineering, chemical production and development is based in Germany while our service engineers are operating world wide.

Our principle is to create innovative and affordable solutions to reduce emission and increase efficiency at the same time.

The «big picture in combustion optimization»

To optimize efficiency in your power plant we analyze your setup from fuel storage to stack emission and provide you a unique, customized solution.

As specialists for combustion optimization, corrosion inhibition and emission control, we offer Additivs and technologies for all fossil fuel fired power stations.

2.8 million tons of CO2 saved in 2020

A perfectly tuned boiler, diesel engine, or gas turbine is not only more efficient and cheaper to operate, it is also more reliable and produces fewer outages.

This gives our clients flexibility in their operations – and the budget savings to invest in renewable technology.